Catalogo

SIMPLY 400

PrintSIMPLY 400 – WET SAW MACHINE 3HP 230V ENGINE – DIRECT TRANSMISSION – SUPPORTS Ø350 AND Ø400 BLADES – CUT DEPTH 14CM IN 1 PASS, 25CM IN DOUBLE PASS (Ø400) – TRANSPORT WHEELS, TABLE HANDLES, LEGS SAFETY CLIPS, GUM CART COVER AND GONIOMETRIC SQUARE OPTIONALLY AVAILABLE

SIMPLY 400

Machine with carriage structure for wet cutting of poroton, tuff, brick and concrete artifacts.

Equipped with a 230V 3HP single-phase engine, supports Ø 350 and 400 mm blades. It can cut up to 140 mm deep in a single run, 250 mm with double run and 70 cm max length.

As for all “New Generation” series Ghelfi machines, its main structure is made of Aluminum: it is therefore extremely resistant to any distortion, resulting in excellent cutting precision over time. Aluminum also means total rust resilience and very long life expectancy.

All Ghelfi cutting machines are manufactured and assembled in our manufacture production plant in Bologna, the same place where for more than over 40 years we continue to accrue an evolving experience in research, design, implementation and assistance on machinery and accessories needed every day by tile, flooring and masory professionals.

We serve the most demanding professionals, or customers with unusual requirements, building on-demand customized machines, or variations of our standard machines, based on their specific requirements.

Why is SIMPLY 400 the best choice?

| ALUMINIUM CHASSIS | Machine’s chassis is made of extruded aluminum profiles, featuring superior robustness when compared to old generation iron-based machines. Aluminum is also unattackable by rust, and very lightweight. Perhaps most importantly, aluminum profiles are virtually undeformable even when the machine is placed on uneven surfaces, all this yelding much better cut precision over the entire product lifetime . |

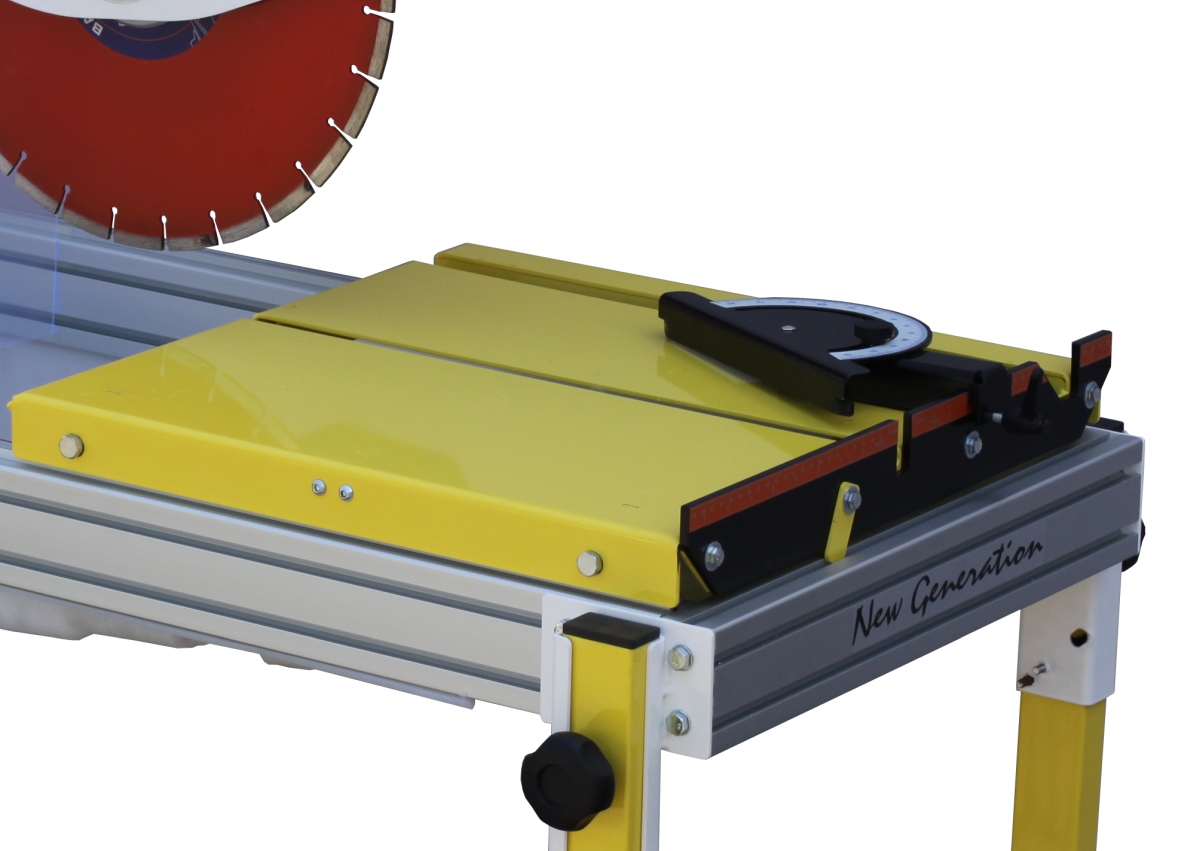

| WORKING CART | The generous-sized (50x50cm) sliding cart is made of sturdy painted metal, optionally equipped with a gum cover helping keep cutting material still while operating. The cart moves onto 4 special stainless steel armored ball bearings sliding onto 2 rails, also exclusively made of stainless steel. Wear resistance is very high, and required maintenance – or replacement – is virtually eliminated, or reduced to exceptional cases. The cart also features a bilateral anti-tilt protection system. A goniometric square tool is also optionally available to ease on diagonal cuts. |

| SINGLE-PHASE ENGINE | A powerful 3HP single-phase engine grants this machine all the muscle needed to cut any kind of brick, along with more solid materials. |

| WATER TANK | The water tank is made of Polyethylene, a very strong plastic material featuring resistance to low and high temperatures, and non-deformable. It is unattackable by rust, and does not leak. Equipped with a handy screw-cap, virtually impossible to accidentally be removed, it is easy to clean. |

| HEAD TILTING SYSTEM | Cutting unit’s built-in vertical tilting system enables the operator to calibrate cutting thickness to the desired value in total safety and ease. |

| MECHANICAL PROTECTIONS | Optional bilateral blade protections reduce water dispersion, water splash, and moreover contribute protecting the operator from accidental blade or debris contact. |

| ELECTRICAL SUBSYSTEM | The machine’s electrical subsystem includes a magneto-thermal safety device protecting the engine for overheats/overloads, and even more importantly a release coil preventing accidental switch-ons following unexpected power supply breaks. |

| WATER PUMP | Based on magneto-inductive technology, it won’t fail/burn even in case of hard jamming. Extremely reliable, no filters to clean, maintenance free. |

| LEGS | To facilitate machine handling and transportation all legs are retractable to reduce overall system size. Rear legs can be optionally provided with wheels to ease local machine movements. Simplarly, all legs can optionally be equipped with a special fall-protection system greatly easing operations even to a lone user. |

|

Ø 350 and 400 mm diamond blade supported |

|

Maximum cutting depth 25 cm on a dual run. |

|

Table size:

W = cm. 50 L = cm. 50 |

| ITEM | DESCRIPTION |

|---|---|

| 1240 | SIMPLY 400 – WET SAW MACHINE – SUPPORTS 350 AND 400MM BLADES |