Catalogo

SQUALETTO FLEX

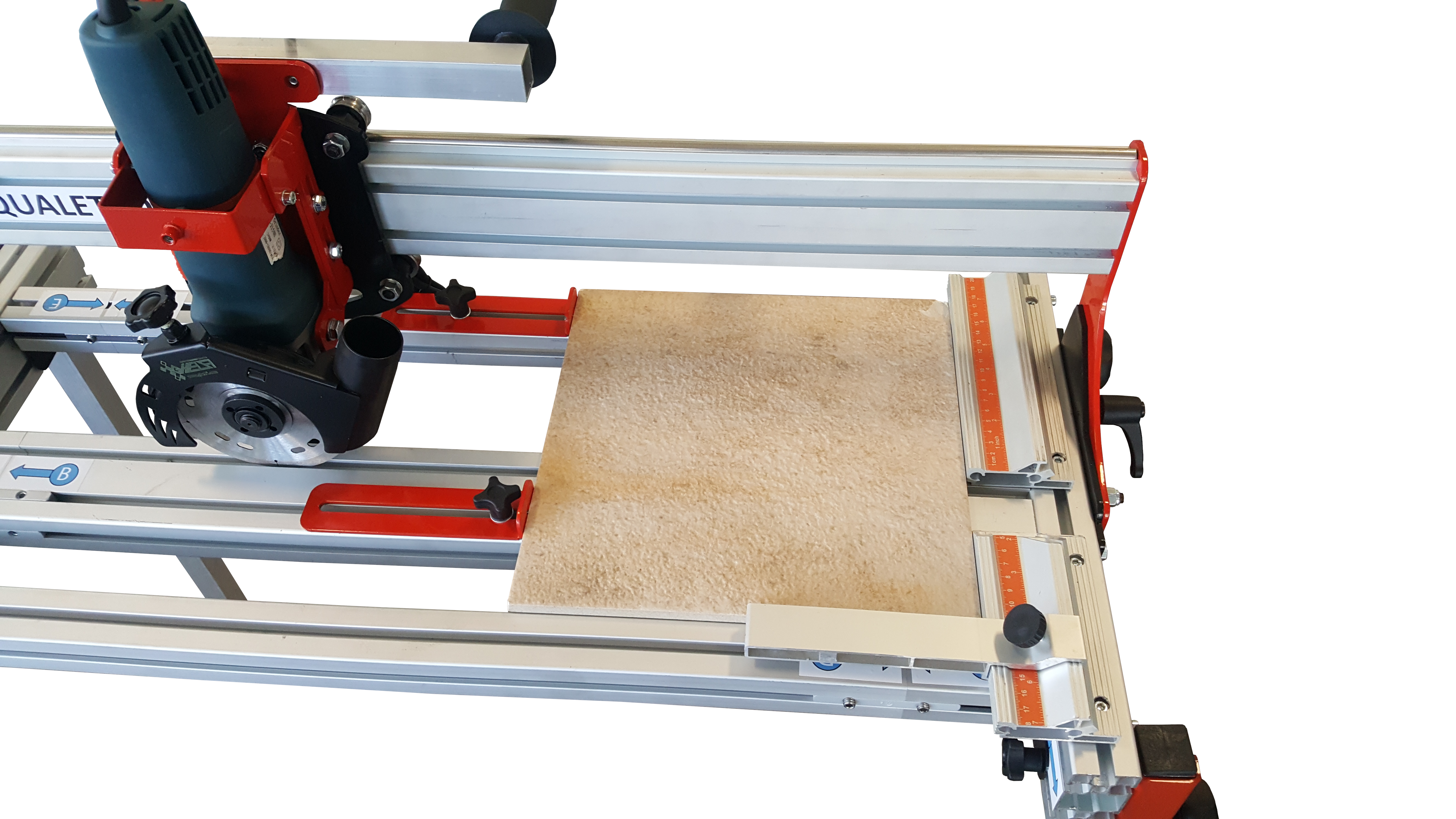

PrintSQUALETTO FLEX – EXTENSIBLE BENCH TO FACILITATE DRY CUT ON SLABS UP TO 410 CM – SUPPORTS STANDARD 125 MM ANGLE GRINDERS FEATURING VARIABLE SPEED AND MIN 1.4KW POWER.

SQUALETTO FLEX

Squaletto FLEX is an innovative cutting bench for slabs and panels of diverse materials. It easily and economically adapts to the slab size, from a few centimeters all the way to 4 meters and more.

With Squaletto FLEX owning, managing and transporting several different pieces of equipment to accomodate for cutting slabs of different sizes becomes a thing of the past. Squaletto FLEX is a single, configurable structure, both lightweight and easily transportable, which can be expanded and contracted to optimise according to the job being carried out.

In its base configuration Squaletto FLEX is 1 meter long, 48 cm wide, 35 cm tall, weighs in at approx 15 kg, and supports cuts up to 60 cm long and 3,5 cm thick. Its capacity grows up to 410cm net cut length thanks to optional 50 or 100 cm extension kits. Each extension kit is compact, lightweight, and easy to install or remove when needed. Similarly, lateral extensions are also available to properly manage extra wide slabs or panels.

Wheels, legs, and all length or width extensions once installed can be removed with the same ease. At the end of a working day a fully expanded Squaletto FLEX can be dismantled in minutes, and goes back to its 100x40x35cm base-size, plus a bunch of bars, all ready to be easily stowed into just about any car’s trunk.

Squaletto FLEX cuts thanks to a standard 125 mm blade high-quality angle grinder. A minimum 1400 W power, and variable 2800-10500 RPM speed support are required. Squaletto FLEX’s grinder mounting brackets allow for the installation of standard 125 mm grinders of virtually any brand.

Squaletto FLEX is designed for dry cut only. Dust can be reduced / collected by a separately available vacuum aspirator. On the blade protection carter a shaped bracket is dedicated to holding an industry-standard aspirator pipe in the optimal efficiency position.

Squaletto FLEX supports all types of cuts usually required on slabs and panels on a professional bulding situation:

- 45° edge (“mitre”) cut is supported by tilting the system’s upper bar on its side.

- Rectangular (“box”) cuts are easily executed by exploting the moving carter’s vertical plunge system.

- Calibrated bases squares and repositionable material fixing profiles (optionally available on some models) greatly facilitate on diagonal cuts.

All Ghelfi systems are designed and assembled in our manufacture production plant in Bologna, the same place where for over 50 years we continue to accrue our evolving experience in research, design, implementation and assistance on machinery and accessories needed every day by tile, flooring and masory professionals.

We serve the most demanding professionals, or customers with unusual requirements, building on-demand customized products, or variations of our standard ones, based on their specific requirements.

Why is SQUALETTO FLEX the best choice ?

| IT EXPANDS AND RETRACTS WHEN AND WHERE YOU NEED | Squaletto FLEX in its base configuration is a very lightweight and compact structure made of aluminum profiles designed to cut tiles, slabs or panels up to 60 cm long and 3,5 cm thick. Its length and width can easily be extended to allow cuts up to 410 cm long by simply installing further aluminum profile bars into the main structure. Length and width extensions are separately available for maximum cost modularity: buy what you need only when you need it. Furthermore, extensions are designed to be easily installed and removed. A fully expanded Squaletto FLEX system can be dismantled in minutes, and carried / transported with great ease, in just a car. |

| ALWAYS PERFECT CUTS, INCLUDING THICK TILES, HUGE SLABS, AND IRREGULAR SURFACES | Squaletto FLEX cuts on various material slabs or panels by means of a standard 125 mm angle grinder. Employing specifically designed blades for each material grants the best precision and speed in all situations. An electrical tool featuring high power (min 1400W ) and variable speed (from 2800 to 10500 rpm) is required for ideal performance. Squaletto FLEX – for example – makes all previous generation large porcelain slabs cutting systems limitations, imperfections and wastes a thing of the past. Forget all “break-up-time” problems endured on traditional tile cutters while working on big, thick or irregular-surface tiles: Squaletto FLEX will cut all that with much greater ease, and less waste. |

| NOT “TILES” ONLY | A Squaletto FLEX expandable system is a great tool when cutting panels made of diverse materials: wood, drywall, pre-coupled and much more. By just using the right diamond blade for each material Squaletto FLEX grants always perfect, on-square cuts with great speed and ease. |

| A SEPARATELY EXPLOITABLE ELECTRICAL TOOL | Squaletto FLEX cuts by means of a high-quality, industry-standard angle grinder. The grinder can be taken off the system at any time, and used freehand for countless other purposes thus furtherly improving on investiment return. |

| ALUMINUM CHASSIS | Squaletto FLEX chassis is made of extruded aluminum profiles, featuring superior robustness when compared to old generation iron-based solutions. Aluminum is also unattackable by rust, and lightweight. Perhaps most importantly, aluminum profiles are virtually undeformable, all this yelding much better cut precision over the entire product lifetime. In its base configuration Squaletto FLEX overall width is 48cm, which can be furtherly expanded by adopting optional side extensions. |

| SLIDING BRIDGE AND MOVING PARTS | The bridge supporting Squaletto FLEX moving head’s horizontal sliding is made of a 40×80 mm extruded aluminum profile. Head movement is supported by 4 stainless steel armored ball bearings, running on 2 rails – one above the bridge, one underneath – also made of 100% stainless steel. Our features offer superior wear resistance, and minimise periodical maintenance / calibration needs. |

| DUST REDUCTION | To reduce or eliminate the dust produced during dry cuts all that is needed is inserting an appropriate industry-standard (separately availabila) vacuum aspirator pipe terminal onto the specific bracket on Squaletto FLEX’s blade protection carter. |

| “MITRE” (45°) CUT | Squaletto FLEX’s horizontal sliding bridge and moving head can easily be reclined sideways to execute 45° (“mitre”) cuts on slab edges. |

| HEAD TILTING SYSTEM | Moving head’s built-in vertical tilting system enables the operator to calibrate cut thickness to the desired value in total safety, and effortlessly execute rectangular (“box”) cuts. |

| LEGS | Squaletto FLEX can be fully exploited while laying on the ground or on any sufficiently sturdy table. Such is the recommended operative situation when the structure is extended by more than 1 mt beyond its base size. Alternatively, the main chassis can be equipped with a set of removable legs transforming Squaletto FLEX into a “dry cut bench”. Legs are very easily installable, and can be removed in seconds at the end of the job to facilitate transport or stocking. A set of 4 legs is bundled on Squaletto FLEX PRO, and can optionally be added at any time on lower tier configurations. Additional legs are also separately available, to support longer and/or wider Squaletto FLEX setups. Installing and positioning additional legs alongside a Squaletto FLEX expanded configuration is very simple and fast, and – like all other accessories – additional legs are easily removed for better transport / stocking at the end of each work session. |

| SKU# | DESCRIPTION |

|---|---|

| 1150 | SQUALETTO FLEX – EXPANDABLE DRY CUT WORK BENCH – SUPPLIED WITH A VARIABLE SPEED 1.5KW ANGLE GRINDER AND Ø 125 MM PORCELAIN DIAMOND BLADE. |

| 1150PRO | SQUALETTO FLEX PRO – EXPANDABLE DRY CUT WORK BENCH – SUPPLIED WITH A VARIABLE SPEED 1.5KW ANGLE GRINDER AND Ø 125 MM PORCELAIN DIAMOND BLADE, 4 REMOVABLE LEGS, 2 MOVEMENT WHEELS, CALIBRATE BASE SQUARES AND ADDITIONAL SLAB FIXING PROFILES. |

| OPTIONAL PARTS AND ACCESSORIES | |

|---|---|

| SKU# | DESCRIPTION |

| 1150 01 | SQUALETTO FLEX – LENGTH EXTENSION KIT – 50CM. |

| 1150 02 | SQUALETTO FLEX – LENGTH EXTENSION KIT – 50CM. |

| 1150 03 | SQUALETTO FLEX – WIDTH EXTENSION KIT – 50CM. |

| 1150 04 | SQUALETTO FLEX – MOVEMENT WHEELS (KIT OF 2) |

| 1150 05 | SQUALETTO FLEX – REMOVABLE LEGS (KIT OF 4) INCLUDES LEG HOLDERS |

| 1150 06 | SQUALETTO FLEX – EXTRA SUPPORT LEG |

| 1150 08 | SQUALETTO FLEX – CALIBRATED BASE SQURES + SLAB FIXING PROFILES |